Gun Drilling

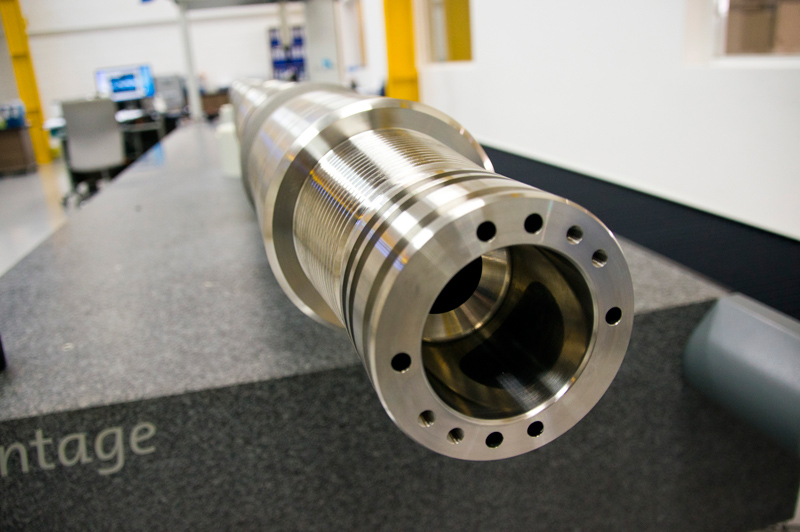

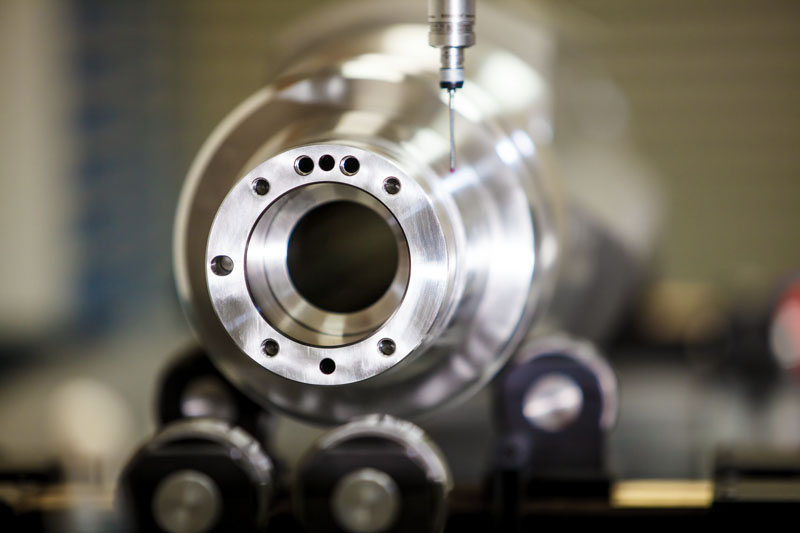

Gun drilling is a flexible and effective method for producing deep or shallow close tolerance holes with smooth surface finishes, usually in one pass, and often eliminates the need for secondary operations such as deburring, reaming, honing and work hardening. A gun drill tool differs from a conventional twist drill by its unique head geometry; a standard gun drill has a single effective cutting edge. Guide pads burnish the hole while drilling, allowing the hole to maintain straightness. The result of this burnishing activity is a very round hole with a precision diameter.

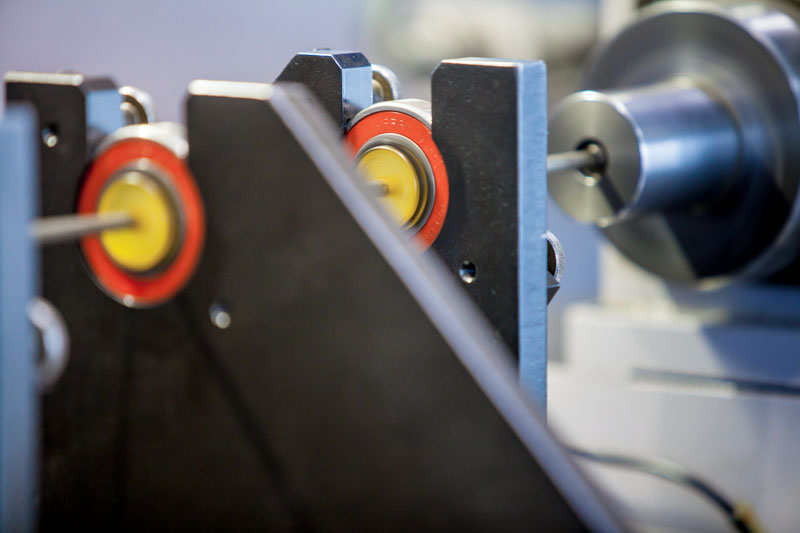

SBOEVN have invested in the latest computer controlled technology to meet all your requirements. Our on-site gun-drilling machines can produce holes in a wide variety of materials from 3mm — 20mm diameter and up to 4,500mm in depth in one pass to extremely high tolerances.